Manufacturer of Grade 1

AAC Blocks

At Nirman N-Lite, we are proud pioneers in the manufacturing of Autoclaved Aerated Concrete (AAC) blocks – the future of sustainable construction. With a commitment to quality, innovation, and eco-friendly solutions, we deliver lightweight yet durable AAC products that redefine modern building standards.

Founded in [2025], our company has grown to become a trusted name in the construction industry. Our state-of-the-art manufacturing facility is equipped with the latest technology to produce high-performance AAC blocks that offer superior thermal insulation, soundproofing, and fire resistance.

We serve a wide range of clients including residential, commercial, and industrial developers, providing them with customized solutions that meet the highest standards of performance and sustainability. Every block we produce is a step toward a greener tomorrow.

Our team of experts is dedicated to ensuring that every product meets stringent quality checks, providing our clients with peace of mind and confidence in their construction projects. We believe in building lasting relationships with our customers, offering exceptional service and support throughout the project lifecycle.

What are AAC Blocks

Autoclaved Aerated Concrete (AAC) blocks are a lightweight, precast, foam concrete building material that offers excellent insulation, structural strength, and durability. Developed as an eco-friendly alternative to traditional bricks and concrete, AAC blocks are manufactured using natural raw materials such as sand (or fly ash), cement, lime, gypsum, and aluminum powder.

The unique cellular structure of AAC blocks is formed through a chemical reaction between the aluminum and the other ingredients, which produces tiny hydrogen bubbles. These bubbles create millions of small, finely dispersed air pockets within the material, making it lightweight and insulating.

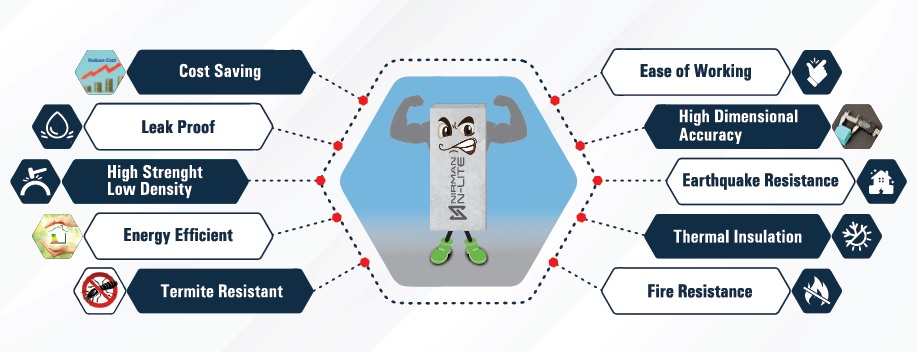

AAC blocks are cured under high-pressure steam in an autoclave, which gives them superior strength and dimensional stability. They are ideal for non-load bearing and load-bearing walls, offering benefits like faster construction, reduced dead load, and better resistance to fire and pests.

- Up to 3 times lighter than traditional bricks

- Excellent thermal and sound insulation

- Quick and easy to install

- Highly fire-resistant (up to 4 hours)

- Environmentally friendly and sustainable

Our Products and Key Features

| Parameter | Nirman N-lite AAC Blocks | Clay Bricks |

|---|---|---|

| Breakage | Less then 3% | Upto 15% |

| Construction Speed | Speedy construction due to its big size ,lite weight & easy to cut in any size and shape | Comparatively slow |

| Quality | Uniform & Consistent | Normally varies |

| Availability | Any time | Shortage in monsoon |

| Energy Saving | Approx, 30% reduction in air - conditioned load | No such savings |

| Chemical Composition | Sand/flyash used around 60-70% which reacts with lime & cement form AAC | Soil used which contain many inorganic impurities like Sulphates etc. resulting in efflorescence |

| Precision In Size | Variation 1.00[+/-]mm | Variation 3.15[+/-] |

| Compressive Strength | 3.5 - 4.5N/mm2 thick wall | 2.5 -3. N/mm2 |

| Sound Reduction Index 1[db] | 45 for 20mm thick wall | 50 for 230mm thick wall |

| Thermal Conductivity [kw-m/c] | It transfer heat between 0.21 to 0.42 W/mk | It transfers heat between 6-10 w/mk |

| Cost Benefit Factor | Saving up to 24% in structural cost due to reduction of dead load (subject to project design) | No such Savings |

| Weight | 550 to 600 Kg/M³ | 1950 to 2000 Kg/M³ |

| Fire Resistance | Can withstand upto 1200°C for 6 hrs depending on thickness | Cannot Tolerate |

| Moisture Resistance | Better than Red Brick | Average |

| Saving Plaster | Overall 35% Cut Down In The Cost Of Plastering | No such saving |

| Environment Impact | Made up of flyash, thus no soil is consumed | Around 32kgs of fertile soil is used to produced one brick |